Key Quality Indicators and Technical Parameters of Fiber Optic Patch Cords

A Technical Overview by TARLUZ Fiber Optics

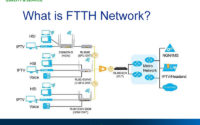

Fiber optic patch cords are essential components in modern optical communication networks, widely deployed in data centers, telecommunications, FTTx systems, and enterprise cabling infrastructures. The reliability and efficiency of an optical network heavily depend on the quality of these patch cords.

At TARLUZ, we specialize in manufacturing high-performance fiber optic patch cords that comply with global industry standards, ensuring optimal signal integrity and long-term stability. Below is a detailed breakdown of the key technical parameters and quality indicators that define premium fiber optic patch cords.

1. Insertion Loss (IL)

Definition:

Insertion Loss measures the reduction in optical power when a signal passes through a fiber patch cord, directly impacting link budget and transmission efficiency.

Performance Standards:

-

Standard patch cords: ≤ 0.3 dB

-

Low-loss patch cords (precision-grade): ≤ 0.15 dB

TARLUZ Quality Assurance:

Every TARLUZ patch cord undergoes 100% insertion loss testing to ensure compliance with stringent performance requirements, supporting high-speed and long-distance optical networks.

2. Return Loss (RL)

Definition:

Return Loss quantifies the amount of light reflected back toward the source, which can degrade signal quality, particularly in high-speed and sensitive applications.

Typical Specifications:

-

UPC (Ultra Physical Contact) connectors: ≥ 50 dB

-

APC (Angled Physical Contact) connectors: ≥ 60 dB

Application Guidance:

APC connectors are recommended for long-haul transmission and GPON/FTTH networks where minimizing back reflection is critical.

3. Connector Types & Polish

Common Connector Options:

-

LC, SC, FC, ST, MU (standard single-fiber connectors)

-

MPO/MTP (high-density multi-fiber connectors)

Polish Types & Applications:

-

UPC (flat polish): Ideal for general data transmission

-

APC (8° angled polish): Preferred for high-precision optical systems

TARLUZ Custom Solutions:

We offer a wide range of connector configurations, including hybrid and loopback patch cords, tailored to meet diverse network requirements.

4. Cable Jacket Materials & Structure

Jacket Types:

-

PVC: Standard indoor use

-

LSZH (Low Smoke Zero Halogen): Fire-resistant, ideal for data centers and public spaces

-

Armored/Ruggedized: Enhanced protection for harsh environments

Cable Configurations:

-

Simplex, Duplex, or Multi-fiber

-

Round or flat designs for flexible routing

TARLUZ Customization:

We primarily offer patch cords with LSZH and Armored jackets to meet the demands of different environments.

5. Ferrule & Endface Geometry

Ferrule Material:

High-precision zirconia ceramic ensures thermal stability and durability.

Endface Quality Control:

Radius of curvature

Apex offset

Fiber protrusion/undercut

TARLUZ Compliance:

All connectors undergo interferometer inspection to meet IEC 61754, GR-326, and TIA/EIA-568 standards.

6. Mechanical & Environmental Reliability

Key Durability Tests:

-

500+ mating cycles without performance degradation

-

Thermal cycling (-40°C to +85°C)

-

Humidity & vibration resistance

TARLUZ Assurance:

Our patch cords are engineered to withstand demanding operational conditions while maintaining optical stability.

About TARLUZ Fiber Optics

TARLUZ is a leading manufacturer of fiber optic connectivity solutions, including patch cords, transceivers, MPO/MTP systems, and DAC/AOC copper cables. With in-house polishing, rigorous testing, and advanced manufacturing processes, we deliver high-performance, reliable optical connectivity for global enterprises and service providers.

For customized solutions and technical support, contact TARLUZ today!

Patch Cords to Connect Inband Equipment to Structured Fiber Cabling