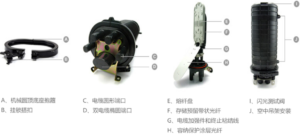

Product Show: Fiber Optic Splice Closures

The fiber optic splice closures (FOSC) belongs to the mechanical pressure sealing joint system. It is a continuous protection device that provides optical, sealing and mechanical strength continuity between adjacent cables. It is mainly used for straight-through and branch connection of overhead, pipeline, direct burial and other laying methods applicable to various structural optical cables. The fiber optical splice closure is a connecting part that connects two or more optical cables together and has protective components. It must be used in the construction of optical cable lines, and is one of the most important equipments. The quality of the optical cable connector box directly affects the quality and the service life of the cable line.

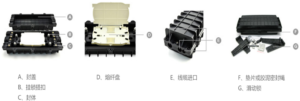

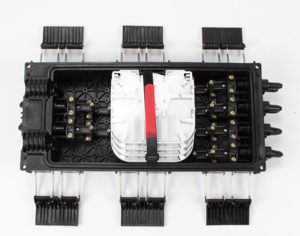

Internal Structure of Fiber Optical Splice Closures

- Support frame: The main body of the internal components.

- Optical cable fixing device: used for fixing the optical cable and the base and fixing the optical cable reinforcing component. The first is the fixing of the cable reinforcing core inside; the second is the fixing of the cable and the support frame; the third is that the cable and the connector box are sealed and fixed by the heat shrinkable sheath.

- Fiber-optic placement device: The fiber-optic connector and the remaining fiber can be stored in sequence. The length of the remaining fiber should be no less than 1 meter, and the remaining fiber-optic disk should have a mean diameter of not less than 35 mm.

- Optical fiber joint protection: The heat-shrinkable protective sleeve can be placed on the core fixing clip in the receiving tray.

- Sealing the optical cable and the joint box: sand the junction of the joint box and the optical cable with the abrasive cloth on the cable and the base cable, wipe the sanding place with the cleaning agent, attach the aluminum foil, and place the heat shrinkable tube in the joint box. At the entrance of the cable, the burner is slowly heated according to the middle and rear ends, so that the entire heat-shrinkable tube can be completely shrunk.

Classification of Fiber Optical Splice Closures

1. According to the shape structure, it can be divided into two types: a cap type cable joint box and a horizontal type cable joint box;

2. According to the way of cable laying, there are overhead, pipeline (tunnel) and direct burial;

3. According to the connection mode of optical cable, it is divided into two types: straight and divergent;

4. According to the sealing method, there are heat shrinkable seal type and mechanical seal type.

5. According to whether the adapter can be assembled, it can be divided into configurable adapter type and non-assemblable adapter type.

6. According to the classification of the shell material, it can be divided into plastic shell and metal shell

Installation of Fiber Optical Cable

1.Select the smallest inner diameter seal ring according to the outer diameter of the cable and place the two seal rings on the cable.

2. Place the fiber optic cable into the corresponding access hole.

3. Connect shield and ground.

4. Wrap a self-adhesive sealing tape between the two sealing rings so that the sealing tape is wound flush with the outer diameter of the sealing ring to form a cable sealing end.

5. Press the sealed end of the cable into the hole of the cable.

6. Pass the hose clamp through the cable rib fixing seat and the cable core bracket, fix the cable to the base of the joint box, and tighten the hose clamp screw until the hose clamp is tightened.

7. Put a nylon cable tie on the cable and cut the length.

8. The remaining unused cable holes should be sealed with a plug. The sealing tape is also wound on the plug and is required to be the same as 5.2.4.

9. Wrap the reinforcing member around the countersunk screw of the splice tray holder and press it tightly.